When you’re looking for a new wood floor, do you really know what you’re looking at? Many people choose something aesthetically pleasing; but what are you actually choosing for your home?

Many times there is a negative connotation about engineered hardwood flooring, people think that it’s a lesser product because it’s not solid; well, I’m here to set the record straight!

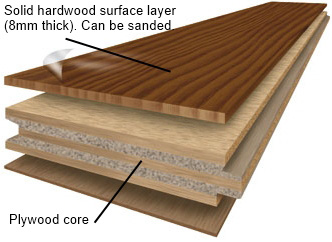

Most of engineered wood flooring is built by having multiple wood layers that are layered, glued and pressed together with high heat and pressure. The middle layers are most of the time either a hardwood and/or plywood. This creates the tongue and groove on either side so your boards can click together when installed as well as ensures superior strength, even to that of some solid hardwoods. The top layer is thicker and made of the hardwood you choose. For example if you’d like a maple engineered hardwood, the top layer of your boards will be solid maple. This layer is then glued and pressed on the top surface of the core. Engineered hardwood flooring is available in almost any wood species. The top layer can then be finished by your installation professional or you can purchase the flooring prefinished.

There are many benefits to using engineered wood floors. Engineered wood flooring has a higher resistance to moisture than solid wood flooring, which adds to their appeal to use in damp basements or on Cape Cod where our salty, humid air can be killer to solid wood floors. Also, some engineered flooring can be glued-down over concrete like in a basement, or stapled down over a wood subfloor like in the rest of the home.

Engineered Hardwood floors range in widths from 3-7 inches wide and in thicknesses from 3/8” – 3/4″, which is also a benefit over solid hardwood, which only comes in 3/4” thick. Engineered hardwood also comes in a wide variety of hardwood species and some are even available in the now popular hand scraped styles.

Some brands of engineered flooring have a thin .6 mm wear layer that can only be buffed and then have an extra coat of polyurethane added to it. While it will give your floors a great new shine and eliminate small scratches and wear, it will not take away large, deep scratches or dents. Unfortunately, these engineered floors cannot be sanded and refinished for fear that the sander might cut in to the plywood underneath, and then you’re flooring is useless and must be replaced. This means they cannot be sanded and refinished new again once they get worn. They have an average lifespan of between 20-30 years depending on traffic, obviously more traffic, less life span. Other brands or styles can have a thicker 2 – 6 mm thick wear layer that can be completely sanded and refinished once or twice if they ever needed to be. These engineered floors can last from 40 – 80 years before having to be replaced which add to their appeal; but also adds to their price.

It’s good to know that engineered wood flooring is resistant to moisture and can be glued down on the concrete. I have been thinking of replacing my floors with engineered wood flooring so it can have more water resistance down the line. I’ll be sure to call around for some deals of engineered wood flooring.